10 ways to save millions asking for advice on energy crops

Biobased industries invest millions in feedstock and supply chains with energy crops. However, finding ways to save millions asking for advice on energy crops, avoiding pitfalls, and mitigating risks in energy crop investments. Moreover, energy crops are being considered for several uses in most countries of the world. Additionally, huge investments in power facilities, cellulose plants, and pelletizers are being made right now, considering a supply chain from residues and plantations. Furthermore, as more species are investigated for biomass as feedstock for power stations, pellet production, biogas digester and gasifiers, or 2nd generation ethanol, more uncertainties are included in the business plans of most companies.

1 – THE BIOMASS SUPPLY CHAIN MAY BE THE HIGHEST COST CONTRIBUTION FACTOR.

Typical projects with energy plantations of perennial grasses and short rotation coppice (trees) will often determine biomass supply costs that are a main contribution to your business plan.

Might lower cost per hectare in marginal lands determine lower inputs and delivered biomass costs per ton in the gate of our facilities?

Changes in yields will be a major driver in farming operation and will largely contribute to your biomass supply cost. Therefore, a reduction level of 20% in assumed yields may often determine changes in the supply chain. Additionally, in the case of a power station, that would mean a lot of money.

For example, assume a power station consuming 200,000 Oven Dry Tons (ODT) per year. Moreover, most commercial projects in the world have established biomass supply costs ranging from 30 to 150 dollars per dry ton. Additionally, in equivalent ranges, this would mean between 3 to 8 $ / GJ of energy delivered (at the gate of the plant). In a 200,000 tons/year supply chain, an OPEX of 4 million dollars per year is a typical supply cost we see every day (assuming 40 $/odt as average costs at the gate of the plant).

Advice on farming operations and determination of average productivity will weigh on decisions made by companies involved in energy plantations.

2 – INCOMPLETE INFORMATION AVAILABLE ON LARGE SCALE PROJECTS

There are already thousands of hectares cultivated with annual and perennial grasses and short rotation woody crops, from poplar and willows in higher latitudes to bamboo and eucalyptus, or Pennisetum purpureum, Miscanthus, and Arundo donax. Additionally, being involved in many projects and supply chain systems with energy crops, allowed us to know that logistics mean as a major issue determining sustainability and economic costs.

Any project in a new location that uses biomass residues and would complete feedstock from energy crops or utilize them as the main raw material source, will surely require to consider past experiences, failures, and success stories. Specifically, it is important to learn from the experiences of others in the industry to avoid repeating mistakes or missing opportunities for improvement.

As scientific and research experiences are not always scalable, the opinion and experience of energy crop experts involved in large scaled plantations should be considered. Additionally, there are many companies, but most of them are involved in one or two species. Therefore, seeking out the input of experienced experts in energy crop production can provide valuable insights and help to avoid potential pitfalls. Many questions may arise:

- Who knows whether there are demonstrated viable alternative crops better suited for my conditions?

- How investors can know about the realistic operational risks of a supply chain?

- How to estimate risks and uncertainties in areas with high productivity potentials where biomass drying and storage systems are difficult to implement using biomass from high yielding species?

- Is there any crop that dries better? Is the selected species the best alternative for pellets considered for final use?

- Which would be the cost assuming harvest efficiencies and transportation costs when establishing a logistic chain of ethanol, biogas, or power/heat production from a certain lignocellulosic biomass crop?

- Is my project possible to upscale considering the Power Purchase Agreement dealt with for the next 10, 15, or 25 years?

In many projects, we see that only partial information has supporting assumptions and assumes local conditions for large scale projects. However, in most cases, that information cannot be replicated or demonstrated to be applicable or extrapolated to project-specific field conditions. Therefore, it is important to ensure that all assumptions are fully supported by relevant data and that any project-specific conditions are taken into account during planning and implementation.

3 – EXAGGERATED YIELDS AND BIASED INFORMATION OFTEN DERIVE IN SCAM

Most companies that promote crops, sell customers planting materials AND consultancies. However, it could make sense, but conflict of interest may be biasing information. Therefore, in any case, it is important to consider the following aspects to ensure that all information and recommendations are objective and unbiased.

- Several huge yield expectations are based only on small trials.

- The performance of varieties and sub-species are found to be similar and usually, companies may claim to have a “Miracle Crop” just to charge companies for its finding.

- Agronomic management and selection of the best strains for the local conditions are the major issues for success.

- Some companies offering species of bamboo for biomass, for example, have never tried biomass plantation patterns (only work in construction sectors). Cutting for biomass implies changes in management and productivity.

- There are companies providing materials of Arundo donax and Pennisetum purpureum claiming unrealistic yields. Some of them have only worked on small scales or in 2 or 3 countries.

- Several considerations need to be done if your project will take place in a tropical area or developing country. Personnel, machinery, climate, and soil conditions but also management will often require a very strict vision and highly focused evaluation to optimize the cropping system and the supply chain.

4 – ECONOMIC, SOCIAL, AND ENVIRONMENTAL CONSIDERATIONS AND RISKS

When setting up a project with energy crops, environmental, social, and economic issues can be a critical aspect to consider. Most sustainable alternatives should consider:

When considering energy crop investments, it is important to also take into account social aspects, employment, and personnel risks. This is because any country has a different culture and workers may require special considerations. For example, we often see two different crops with the same yield and costs per delivered biomass, but one may require 30 jobs and the other only 3. Therefore, depending on local conditions, you will need to analyze the best alternative species to be selected as well as the machinery available.

When planning and implementing energy crop projects, it is crucial to consider environmental issues at every stage of the process. From the selection of the proper species as energy crops for feedstock to the real implementation on a large scale, the project has to consider a wide range of environmental factors. For instance, a project based on crops producing renewable energy often requires a life cycle assessment. Also, reductions in footprint, low impacts on underground and surface water, and considerations regarding fertilizer and nutrient leaching, as well as carbon sequestration. Therefore, environmental considerations should be taken into account from the very beginning to ensure that the project is sustainable and has a positive impact on the environment.

A crop might reach up to 6 meters in height and one can be enthusiastic about it. But your main concern is the final cost in terms of $/GJ delivered to the gate of the facility. Selecting species considering farming and logistic costs is easier when an expert is on your team.

5 – ESTABLISH LIFETIME SCOPE FOR YOUR PLANTATIONS IN YOUR EXACT LOCATION

When developing a business plan that involves the production of biomass from dedicated energy crops, it’s important to consider factors like depreciation and the lifetime of the crops. This is especially important for perennial species, including trees, shrubs, short rotation forestry or short rotation coppice, and in perennial grasses like Giant King Grass, Miscanthus, Arundo donax, Switchgrass, Cynara cardunculus, and many other species. As such, a good estimation of a particular lifetime and for the specific conditions will be required for any such project. By taking these factors into account, businesses can better plan for the future and ensure that their operations are sustainable over the long term.

Most companies that provide planting materials don’t necessarily know or can provide their customers with scientific or successful commercial information on the plantation lifetime of each material they offer. Considering 5, 10, or 30 years will change dramatically your expectations.

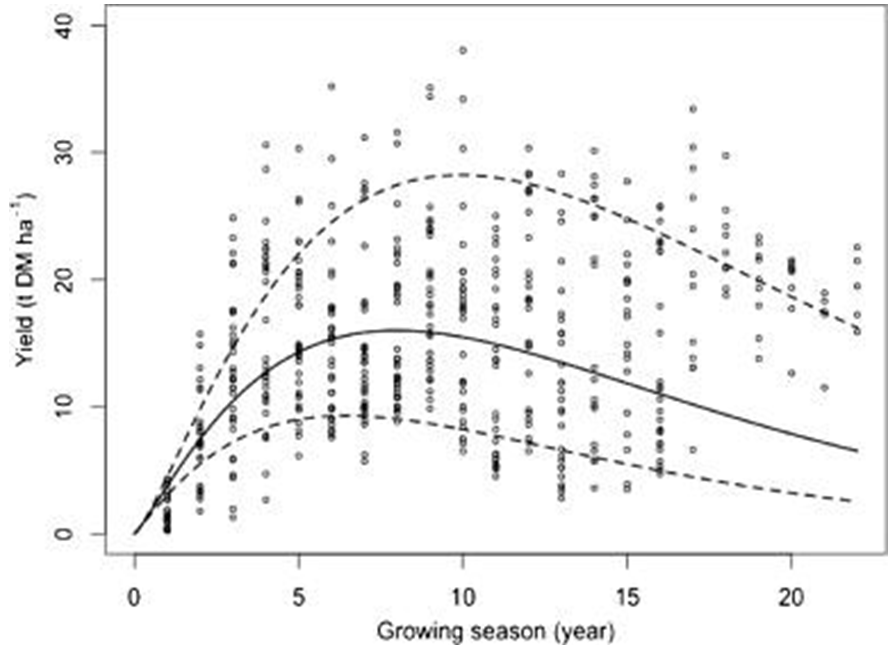

6 – YIELD EVOLUTION DURING THE LIFETIME OF PERENNIALS IS A KEY ISSUE

To understand the dynamics of perennial cropping systems, it is important to consider the specific yield curve during their lifespan. Factors such as soil type, climate conditions, nutrient availability, irrigation, and cutting management can have a significant impact on the roots, rhizomes, and other parts of the plant. Typically, the yield curve will show a maximum yield, followed by a plateau, and eventually a decline. The decreasing yields are usually attributed to plant reserves and source-sink carbon allocation relations, as well as plant physiology. It’s worth noting that land and climate also play a role in determining the establishment costs and operating expenditures.

Furthermore, consider that a supply chain is a critical part of any project. Biomass residues and lignocellulosic crops, moisture levels, and harvesting techniques will require realistic yields which will turn out to be a key issue A simple example could be the following (numbers are only for reference):

A project with 1000 hectares producing 20 dried tons per hectare per year, will have 20.000 tons that could cost (production cost loaded on trailer) within a range of 20-70 $ / ODT.

Assuming an average cost of 40 U$D and no additional transportation costs, this project would have a supply cost of 20000 tons x 40 U$D: 800.000 U$D per year.

An expert’s advice may help reduce that cost or detect any flaws in the production or supply chain.

7 – CONSIDER MUCH MORE THAN A SINGLE OPTION

Most projects focus on renewable energy and sustainability alternatives. However, it’s important to note that most of them promote a monoculture. Therefore, considering more than one single option may determine a risk reduction strategy through diversification. This is crucial as pests, diseases, climatic catastrophes, or unexpected events may always be present during the project’s lifetime. Consequently, preliminary knowledge and information will lead to the right decisions.

Sustainable projects may also consider:

- More than one feedstock will increase biodiversity in your area

- Some crops yield less but cost much less than others. Your goal is a low cost ($/t) at the gate of the destination.

- Residues collection may reduce land use changes and reduce costs

- Integration of bioenergy crops with the food sector in rural areas (biomass alternative uses and markets could be synergic)

- Some facilities can be flexible using herbaceous and woody raw materials from several species

- More alternatives often determine lower risks and lower costs in the long term.

8 – PRODUCTIVITY IS ALWAYS LINKED TO FARMING METHODS. WET AND DRY BIOMASS IS NOT THE SAME.

Similar crops do not allow drying in different climatic conditions. Above: Miscanthus harvest (note crop senescence) during winter time in the UK. Below, grass cuttings and silage chopper in sorghums

In the biomass industry, seed and plantlet suppliers, as well as independent agencies, may provide unrealistic yields for dry matter production. However, when evaluating biomass for pelletization or combustion in a boiler, it is crucial to have an accurate assessment of its quality. While management techniques like grass cuttings can increase productivity in perennial species, they may also affect quality and composition. Therefore, it is important to carefully evaluate the quality and composition of the biomass for the intended end-use.

Frequent cutting of a crop throughout the year can result in higher light interception leaves and leaf area index (LAI) during the year. This allows for regrowth and, in turn, higher annual biomass production if multiple cuttings are permitted. However, the decrease in yields can be determined by soil and climatic interactions with genotypes. Furthermore, producing both wet and dry biomass requires significant alterations in crop management.

Perhaps something a supplier will not necessarily mention is that as lignification is required to avoid high moisture levels, your crop will need to consider senescence and the drying process in the field. Except, you are willing to assume energy costs on technologies for drying or squeezing methods. Agronomical management strategies could be important to reduce moisture levels on the ground. Not all conditioners are well suited for all crops and harvesting periods. After harvesting, other collection systems need to be considered, for example, if biomass bales or chips are required. In general, all drying methods will necessarily imply reductions in productivity as radiation use and photosynthesis activity will both be lower compared to several grass cuttings. This is particularly relevant in tall tropical grasses in areas with rainfall levels higher than 1000mm or in areas where harvest periods occur during months with higher rainfall.

An expert’s advice should tell you the annualized costs ($/gigajoule delivered) to expect both at the farm gate and at the gate of your facility after transportation is considered. From species selection to agronomy and harvest management, transport costs may be different considering the moisture level and volume. To avoid water trucking, a good feasibility study to improve logistic issues in your specific region/land will be probably required.

9 – EXPERIENCES IN OTHER REGIONS OF THE WORLD COULD SAVE YOU MILLIONS

Having been involved in both research programs and consultancy projects, we have observed that companies often encounter similar issues that are common in other regions as well. For instance, Paulownia trees and Jatropha are typical examples of crops that may not be well suited for certain areas. Therefore, experiences of success and failure in different regions and circumstances can enhance any decision-making process, thus reducing risk and investment costs.

10 – INDEPENDENT EXPERTS CAN OFFER INVESTORS REALISTIC YIELDS FOR PLANTATIONS

Most crop specialists and scientists use the information on small plots with a lot of biased information. A small parcel only gives non-realistic information and yields potential about the species. Secondly, any company involved in trading biomass, planting materials production, genetics, seeds, or machinery services could make really good money from a project if one keeps only one option and advice. Therefore, an independent expert will drive you on a safe path, avoiding scams or side effects that may not have been considered by a product supplier. Finally, an integrated vision of farming, logistics, energy, and selection of species can have huge implications for social, economic, environmental, and energy issues in a project

Huge yields of 70-140 dried tons per hectare per year in any species are not typical nor possible in average terms. Experience in many crops and regions worldwide will allow proving that such yields are exceptionally rare and do not necessarily lead to a lower marginal cost.

From Jatropha myths in some countries to several unviable crops and huge environmental impacts from unexpected factors, farm and business failures can be seen everywhere. Usually, the most common reason is the lack of proper advice and integral evaluations.